The logo is in the style of the period: circle, play with letters.

In 1933, Henry Gormand's children appeared in catalogues at the wheel of Mavic pedal cars. Very popular in the thirties, Mavic made two models that were exceptional for their time: spoked wheels with hubcaps, chain drive for the rear axle, soft top and rear trunk. Produced in limited numbers, they remain rare and impossible to find. The only exception is a 'Championnat' model discovered by a Parisian collector and now back in our HQ at the foot of the French Alps.

In 1934, the 'Bavolet Mudguard' was one of the brand's flagships, but it was the 'dura' eyelet rim that stole the show. On a hollow Duraluminium rim, Mavic created a kind of 'tube' called an eyelet, which supports the tension of the spokes through the lower and upper walls of the rim. The Italian Mario Longhi perfected the same process and filed his patent on 5 January 1934, two hours before Mavic! He let Mavic exploit this innovation under licence until 1947. These rims weighed 750g (compared with 1.2kg for standard steel rims) and Antonin Magne tested them in the greatest secrecy (they were painted the colour of wood) in the 1934 Tour de France. His yellow jersey is perhaps no stranger to our favourite colour. From then on, Mavic products would be associated with races and champions.

Aerodynamics inspired the first Mavic wheels. The wheel became an essential concern for our engineers, who drew inspiration from the first aerodynamic studies. In 1973, the Research Department worked on a fibreglass lenticular wheel, the first to be designed by Mavic. Tested on the track and on the road, it was never used in a race, however, as the regulations prohibited it. However, aerodynamic studies had already been taken into account, and Mavic made them a focus of its research.

During the races, Mavic made "neutral and free" assistance available to all riders, based on two key ideas: placing a fully-equipped car in front of the peloton to provide immediate assistance to those who escaped, and offering a complete radio link service between the cars (organisers, doctors, team managers, journalists, etc.). Mavic's first race assistance service dates back to the 1973 Paris-Nice race. It was when Bruno Gormand offered his car at short notice to a team manager who had broken down during the Critérium du Dauphiné Libéré in 1972 that he came up with the idea of providing this "neutral" assistance service, which was totally innovative and better suited to riders and organisers.

In 1975, a number of innovations were introduced. These included the first anodised rims, with a treatment that increased the hardness of the rim walls and protected them from corrosion. Coloured rims appeared on the market for the first time: silver, gold or blue. This is the famous SSC Blue. Never before seen in racing.

That same year, Mavic innovated in bearings and created the 500 hub. Sealed annular bearings, flanges adapted to accommodate the spoke head and bend. It was soon "adjustable and removable", becoming the 500 RD. With this new quality of bearing, Mavic created a bottom bracket with a one-piece body and perfectly aligned sealed ring bearings: the 600 RD.

The clincher rim goes down in cycling history. This was the first double-deck rim with hooks to accommodate a high-pressure tyre developed by Michelin, the Elan tyre. With this patented concept, Mavic developed a new generation of clincher rims that benefited from all the latest technological innovations. In the world of racing, the use of tubular tyres gradually declined in favour of clinchers.

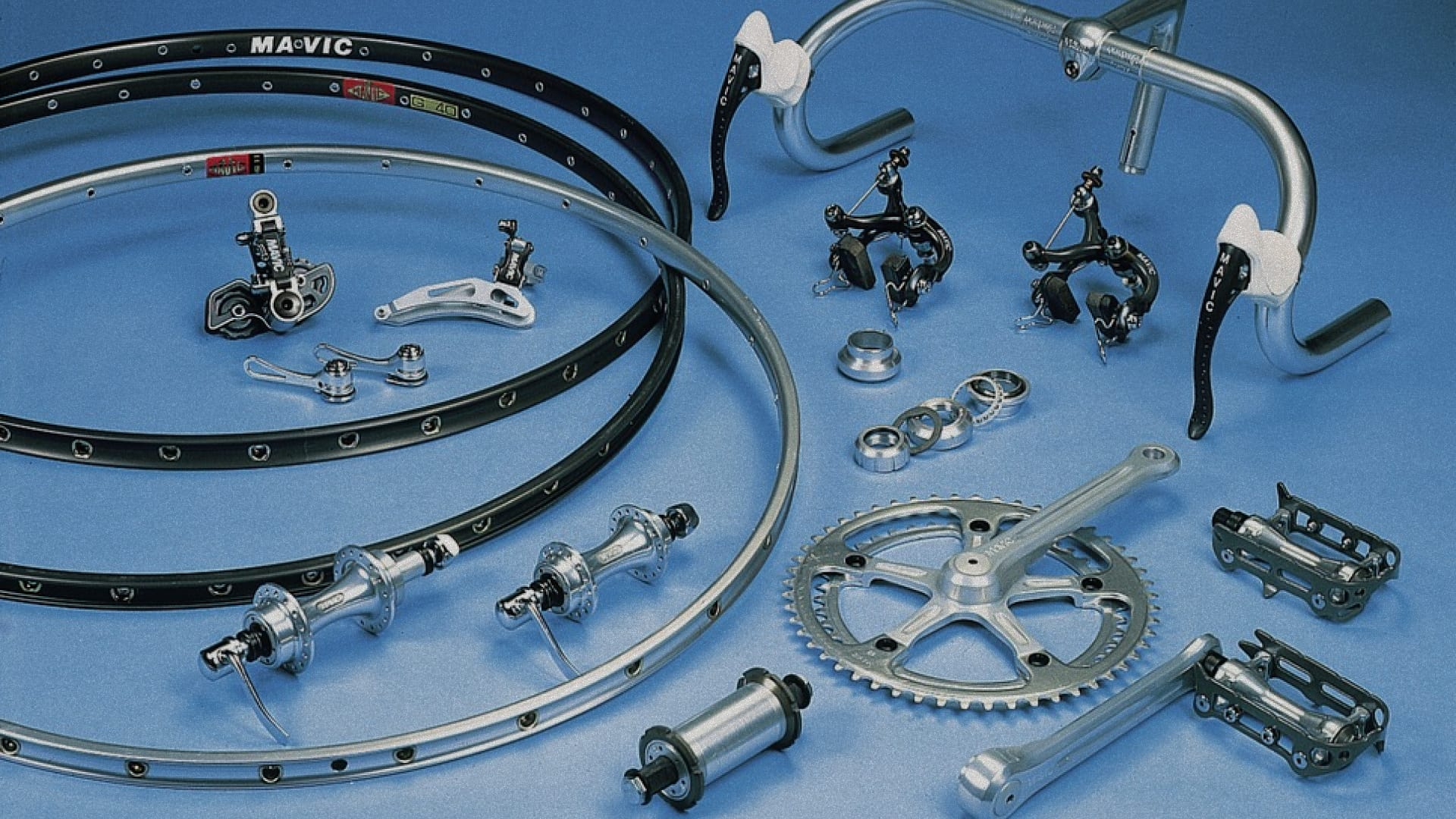

In 1979, the "Tout Mavic" made the brand part of racing history. Mavic, which already manufactured hubs, bottom brackets, headsets, pedals and chainrings, created the famous "Tout Mavic" sets. One example is the 1000 Spécial Service Courses set with SSC Grise Paris-Roubaix and G40 rims, which Sean Kelly used to win the 1984 Paris-Roubaix.

For some time now, the brand's thinking has focused on wheels, on complete creations rather than assemblies. Young Californians looking for a thrill were turning traditional cycling on its head and launching BMX (Bicycle Motocross) and Mountain Bike. Mavic immediately realised that these off-the-beaten-track disciplines, which broadened the range of cycling activities, were not just passing fads. The brand embraced these practices and marketed its first dedicated wheels in 1983. It was the TTM 504 for BMX, with 20-inch TTM 4 rims and a TTM 560 hub derived from the famous 550 Service Courses. Two years later came the first MTB rims, the M4 and M5, with "hard coat" treatment.

In 1984, Mavic Air Department was created to market ultra-light aircraft (ULM), assembled or in kit form. Two models: the Avid Flyer, of American origin, and the French-designed Air Plume. The latter were assembled at Villeneuve near Saint-Trivier-sur-Moignans. But sales did not exceed a few units. The sudden death of Bruno Gormand in December 1985 put an end to this activity. However, the Cessna aircraft acquired by the company provided the radio relay for the races until 1986.

The Comète carbon fibre and Challenger light alloy paracular wheels were launched in 1985. The following year saw the launch of the Comète "+ and -": 12 cells on the periphery accommodate steel weights from 130 to 780g. Riders weighted the wheel to a greater or lesser extent depending on the event.

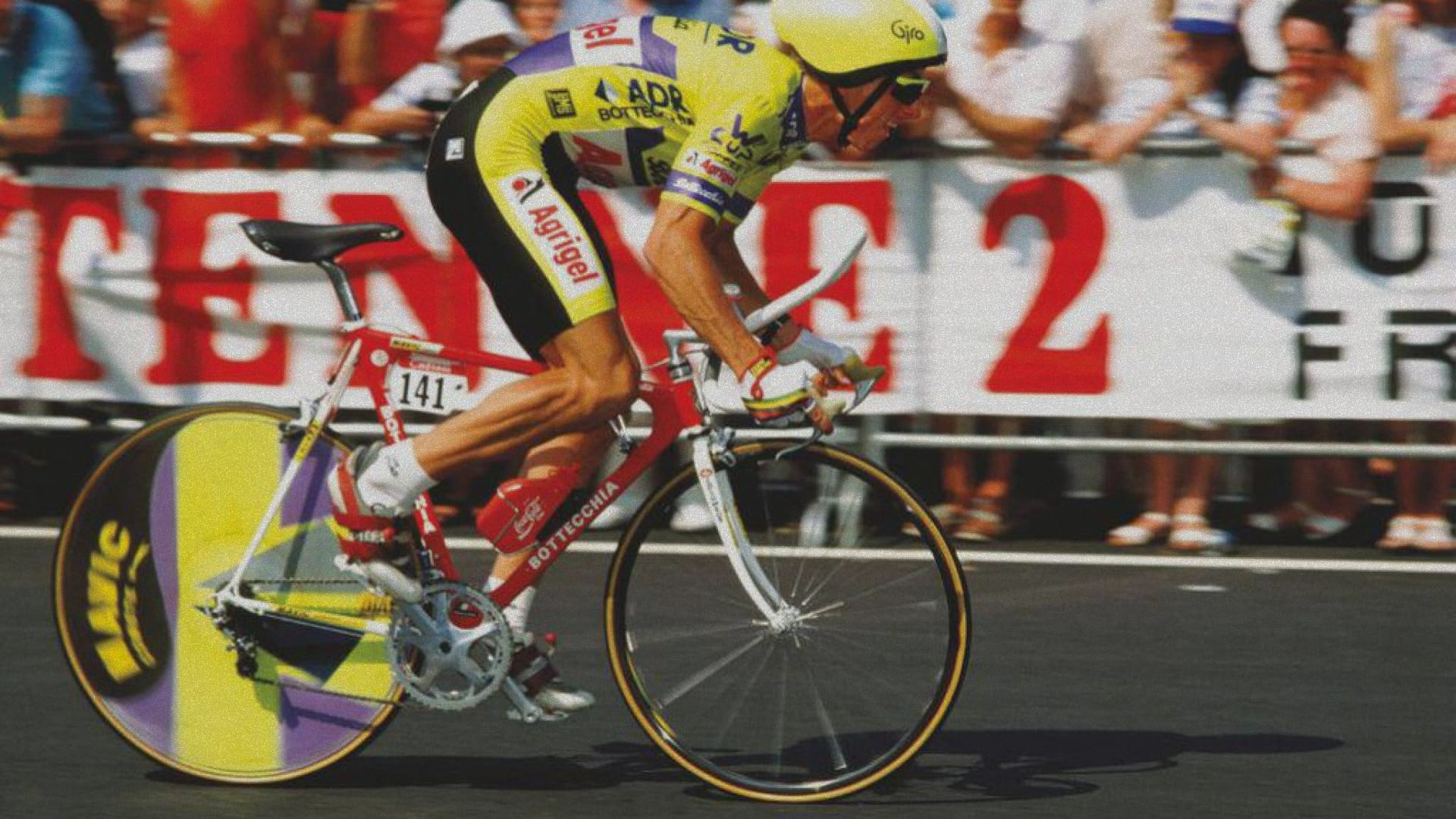

In 1989, Greg Lemond won the Tour de France on an all-Mavic bike. It was an unprecedented victory that went down in the history of the Tour: the final margin over Laurent Fignon, in second place, was 8 seconds.

In 1992, the 3G wheel with profiled front and rear spokes and interchangeable hub cartridges made headlines at the Barcelona Olympics with Chris Boardman.

Mavic worked on an electrically-controlled derailleur which was tested by the Once and RMO teams in the 1992 Tour de France. It was a revolutionary innovation. The following year, Mavic launched the ZMS (Zap Mavic System), the first microprocessor-controlled rear derailleur. Two buttons in two strategic places on the handlebars are used to shift gears up or down. Just a touch and the microprocessor installed in the handlebars transmits the information in real time to the derailleur's electromagnets.

Mavic supports passion and challenge. KL (kilometre thrown or speed mountain biking) on snow is a good example. The dream of Christian Taillefer, Anne-Caroline Chausson and Eric Barone: to shatter all speed records in excess of 200 km/h by launching themselves from the top of a near-vertical track. Mavic wheels. Nails essential.

The wheel as a global system, it was with this approach that Mavic designed the Cosmic. It was marketed in two versions in 1994: Cosmic alu and Cosmic Carbone. 16 stainless steel spokes profiled at the front and rear are arranged in a particular way: straight radial on the front wheels, crossed on the rear wheels. The number, shape and position of these spokes vary from version to version. From research to patent applications, Mavic developed spoke heads and bodies, their positioning and their attachment to rims and hubs, constantly improving the wheel's performance.

In 1996 came the Helium wheel, with its red rims and hubs, the first complete ultra-light wheel designed specifically for mountain use, and the Crossmax, the tough, lightweight "outlaw wheel". Designed specifically as an overall 'system', the Crossmax wheel features an oversized profile and ultra-thin wall, an FTS rear hub and a quick-release system. It has 26 spokes at the front and 28 at the rear, with 3 crossed spokes on the freewheel side and radial spokes on the opposite side. Used at the Atlanta Olympics.

In 1999, Mavic presented the Mektronic, the first wireless electronic drivetrain. Another step forward in electronic derailleur technology, this time the transmission was wireless, using digitally coded radio waves, and there were multiple control points: integrated into the grips and on an on-board computer mounted on the handlebars. This multifunction computer displays speed, distance travelled, elapsed time, cogs selected, etc.

In 1999, Mavic brought together the two tyre giants, Michelin and Hutchinson, with one objective in mind: tubeless tyres. The result: the Crossmax UST Tubeless wheel. A groove in the rim profile accommodates the tyre beads during fitting. When the tyre is inflated, the beads press against the walls of the groove, then rise up and clip under the hooks on the rim. The ability to drive with less pressure without a pinch puncture significantly improved traction and cornering.

In the same year, Mavic took a technological leap forward with its system approach, challenging the norm. The brand developed the Fore concept, a technological innovation derived from aeronautics, and designed the Ksyrium and Crossmax wheels. The spokes are fixed by a threaded tunnel obtained by pushing the material onto a single wall of the rim. End of rim drilling. The result: a watertight rim, no rim tape, fewer spokes, a lighter wheel and greater rigidity and strength.

In 2002, Mavic registered the ISM (Inter Spoke Milling) patent, protecting the mechanical process of machining the upper bridge of the rim between the spoke fixing holes. This innovation reduces rotational mass (reducing inertia) and cuts rim weight by almost 10-20% without altering strength, thus improving performance.

In 2003, Mavic came up with the innovative Wintech cycle computer, which won the Grand Prize for Innovation in the United States the same year it was launched. Its special feature: the sensor is located in the quick-release lever on the front wheel and the data is transmitted wirelessly to the receiver via a coded digital link that is immune to interference.

2007 saw the creation of R-SYS, the third generation of tubular carbon-spoke wheels based on the TraComp concept. TraComp technology prevents the spokes from loosening and maintains the wheel's lateral rigidity under high stress. Tubular carbon spokes fixed to the rim and hub limit deformation and misalignment of the wheel (sail-gripping), minimise material fatigue by reducing spoke tension (longer life), maximising weight reduction and the performance of the complete wheel.

2008 saw the launch of a range of Mavic pedals. Following on from the innovative 646 LMS of 1990, this new range includes three road models. On these items, the emphasis has been placed on energy transfer, the fluidity of the bearings and the resistance of the cleats to wear. The flagship of the range, the Race SL Ti with titanium axle, weighs in at just 110 grams.

In 2008, Mavic launched a complete range of cycling shoes, textiles and accessories. This extensive range includes innovative equipment that perfectly meets the expectations of the most demanding cyclists. These innovations cover materials, accessories and technical and functional cuts.

The products are designed for all types of cycling, whether road, triathlon or mountain bike, and to meet the needs of both men and women.

In 2010, for the first time, wheels are designed to include their own specific tyres. By developing wheel and tyre technologies together, Mavic is entering a new era of wheel design and can improve the responsiveness of the system.

Drawing on its in-depth knowledge of cycling and cyclists, in 2011 Mavic is launching a complete range of helmets using the latest technologies to offer lightweight, aerodynamic and safe products. Proven at the highest level of competition, these helmets are among the best on the market.

In 2015, the KSYRIUM Pro Disc Allroad is the first reliable road tubeless based on the Universal System Tubeless standard. A design optimised for comfort and performance, the legendary reliability of Ksyrium and two tyre options for a solution suited to all conditions.

In 2017, Mavic is celebrating 40 years of partnership with the Tour de France. Since 1977, riders in the world's greatest cycling race have benefited from our yellow neutral assistance cars.

That same year saw the launch of the Comete Ultimate Shoes, the new shoes that are fully connected to the bike. Featuring a carbon shell with minimal material flex, Comete Ultimate Shoes offer a 19% increase in the foot's range of movement, as well as an ultra-low stack height of 4.5 mm, for a 15% energy saving.

2018 sees the introduction of the new Instant Drive 360 freewheel system, which is lighter and guarantees extremely fast engagement, with a point every 9°. An oversized non-contact rubber seal reduces friction to a minimum, and a wide choice of adapters makes it compatible with all types of frames and axles, for use on all MTB wheels in 2019 (except Deemax DH).

In 2020, with the takeover by the Bourrelier Group, Mavic returned to being a family-run SME with agile and autonomous governance, refocusing on the products that have made the brand so successful.

2021 saw the launch of Fore Carbon, the first "real" tubeless wheel without a rim tape. Mavic is the only brand to offer an anchoring point for spokes that provides such rigidity on such a light rim. An aluminium insert is moulded into the rim, between the layers of carbon, to ensure a reinforced junction between the spoke and the rim.

The logo is in the style of the period: circle, play with letters.

First change to the logo: end of the circle, beginning of the diamond.

The yellow diamond is set in a red rectangle with rounded corners. This is the logo that will be used on Mavic assistance vehicles.

The brand is set on a parallelepiped with a yellow background. The italicised letters give the logo more movement. It is now identical on all media: cars, catalogues, products, etc.

The end of the parallelepiped, the beginning of the oval. Mavic places itself at the heart of the movement and amplifies it with the black lines on either side.

Yellow is part of the history of Mavic and its logo. It represents strength, passion and victory.

Mavic is becoming inclusive, promising to offer every cyclist (road, MTB, gravel, urban, triathlon) products adapted to the way they practice their sport.